Why

Much of our country lies below sea level. The Afsluitdijk has been protecting large parts of the Netherlands against flooding by the sea since 1932. However, the dike is due for regeneration. It no longer complies with current legislated water safety standards. The climate is also changing. This leads to a rising sea level and more frequent extreme weather conditions. The dike must continue to protect us against floods in changing conditions.

How

On the side of the Wadden Sea , we will increase the height of the dike by almost two metres and reinforce it with innovative concrete blocks. We will reinforce the top of the dike with Quattroblocks and the bottom of the dike with Levvel-blocs. The water pressure on the dike between Kornwerderzand and the Frisian coast is not as great. This is why we will not use Levvel-blocs to reinforce the bottom of the dike here, but rather use a smaller version of the Quattroblocks. The dike will also be able to withstand surge overflow. The dike’s inner side, on the IJsselmeer (Lake IJssel) side, is able to withstand a wave surge of 10 litres of water per second per metre. We will also create a recreational cycling and hiking path on the side of the Wadden Sea.

Innovative concrete blocks

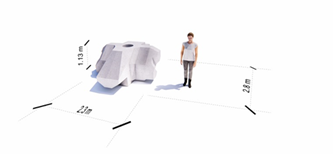

Building consortium Levvel has developed innovative concrete blocks specifically for the Afsluitdijk. The Levvel-blocs are so strong that they can withstand waves crashing into the dike during a heavy storm. Thanks to the shape of the block, 200,000m3 less concrete can be used. This leads to 56% less CO2 emissions. The Levvel-blocs weigh 6,500 kg each. They can be connected to each other like Lego bricks and will break the waves during heavy storms. A rough top layer and two small notches at the top will enable salt tolerant plants, currently also present on the dike, to return to the Levvel-blocs. A special crane pontoon – the Titan – will place the Levvel-blocs at a pace of 35 metres per day. We will place a total of 70,000 Levvel-blocs.

Levvel produces around 100 blocks per day using a fully automated process in the dedicated plant in Harlingen. Each block has a chip for easy tracking during manufacturing, storage, and transport. We bring the blocks to the dike by ship and place them using a floating crane pontoon. This alleviates the road and allows the dike to remain open for traffic during the work. We will demolish the plant after the project.

Adaptive Delta Management

The renovated Afsluitdijk will comply with current legislated water safety standards until at least 2050. By implementing smart measures now, it will be possible to further reinforce the dike in the future with relatively simple interventions. This is what we call Adaptive Delta Management. For example, the revetment on the dike’s sea side will last at least 100 years. Furthermore, should this be necessary in the future, greater wave surges can be accommodated by further reinforcing the IJsselmeer side of the dike/

When

The work has started in 2019 and has been completed in 2023.